Every construction project, no matter how big or small, begins with a crucial step known as the “construction takeoff.” But what exactly is a takeoff in construction? If you’re new to the industry or just looking to broaden your understanding, we’ll shed light on this key process.

A construction takeoff, also known as a quantity takeoff, is a detailed breakdown of all the materials, labor, and equipment needed to complete a construction project. It aids contractors in providing accurate estimates, making successful bids, and efficiently managing the construction cost throughout the project lifecycle. This process can be a manual takeoff, performed on paper blueprints, or a digital takeoff, utilizing powerful software tools for greater efficiency and accuracy.

Comprehending the intricacies of a construction takeoff and why it serves as the foundation for any successful construction project is essential. There are various types of takeoffs, with the most common ones being quantity takeoff and material takeoff.

A quantity takeoff is an exhaustive count of every item that will be needed to complete the construction project. This includes literally everything—from the number of light fixtures that need to be installed to the volume of concrete required, right down to the square footage of paint needed for the walls. Attention to detail is crucial here as an inaccurate takeoff can inflate the final construction cost and lead to additional costs.

Material takeoff, on the other hand, focuses on the raw materials needed for the project. Every item is listed and coded to streamline the ordering process, facilitating accurate and efficient procurement of required materials. Material takeoff ensures that you stay on top of your resources and maintain a steady workflow.

A manual takeoff involves analyzing paper plans and manually estimating the quantities. Although tried and true, it is a time-consuming process prone to human error.

Digital takeoff leverages powerful construction takeoff software tools to speed up and simplify the process. It allows construction professionals to draw directly on digital blueprints, automatically calculating accurate measurements. A digital takeoff can be a game-changer, especially for larger projects, offering precise measurements and estimation at a much faster rate, without compromising on accuracy.

The goal of these processes is to produce an accurate estimate, which is key in providing a solid base for the project. Whether it’s labor costs, material costs, or the bidding process, everything in a construction project hinges on the quality of the takeoff. An accurate estimate is not just about winning bids; it’s also about generating profitability and long-term success for your construction business.

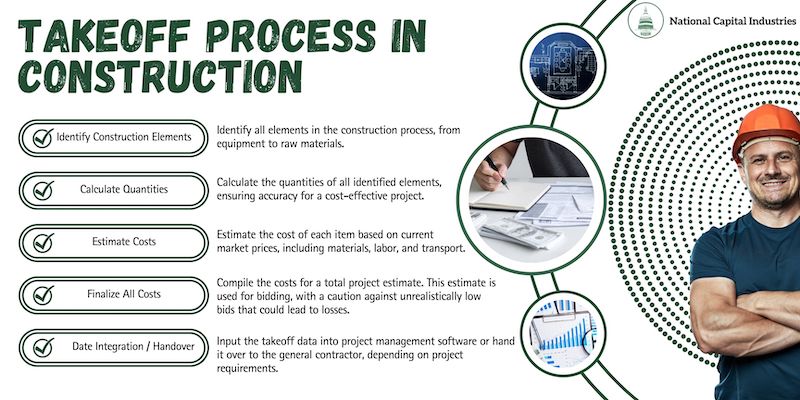

The first step involves using the construction drawing or blueprint of a project to identify all elements in the construction process. These elements can range from simple things like the quantity of light fixtures to complex aspects like the square footage of a building. Ensuring accurate measurements at this stage is critical to avoid inaccurate takeoff.

Once all elements and raw materials are identified, your next move is to calculate their quantities. This process involves a fair bit of tedious labor as you need to count every nut, bolt, and brick required for the project. However, remember that accuracy here is paramount to a cost-effective, successful operation.

After quantity calculation, you estimate the cost of each item based on current market prices. You’ll need to include every relevant cost—material costs, labor costs, and even transport. Given the market fluctuations, ensure you keep this estimate as recent as possible.

Up next is the summing up of these costs for a total project estimate. This overall estimate could then be used as your bid in a competitive bidding process. Remember, while your goal is to keep costs low, an unrealistically low bid resulting from an inaccurate takeoff can lead to losses.

Lastly, you take your takeoff data and feed it into your project management software or hand it over to your general contractor, depending on project rules and requirements.

It’s important to note that while this might sound straightforward on paper, it’s often a meticulous and time-consuming process in practice. Manual takeoff can be daunting, especially for larger projects, and that’s where digital tools step in to simplify and expedite operations.

The rise of digital technology has reshaped many industries, and construction is no exception. The shift from manual methods to digital tools presents many benefits, especially when it comes to construction takeoffs.

Traditionally, a manual takeoff involves pouring over paper blueprints, and performing calculations by hand, a process that can be incredibly time-consuming, particularly for larger projects. More importantly, manual takeoffs are prone to human error, which can lead to an inaccurate takeoff resulting in increased costs and project delays.

Enter digital takeoff software. These modern tools have revolutionized the construction takeoff process, offering a way to automate and simplify measurements and calculations. Programs like Autodesk Takeoff and other digital takeoff software allow construction professionals to work directly on digital blueprints, automatically converting measurements and calculations into project estimates.

These digital solutions outshine paper blueprints by enabling contractors to perform takeoffs more quickly and with greater accuracy. Digital blueprints can be easily adjusted or scaled, which is a valuable feature when dealing with changes in project requirements. Accommodating such changes on paper blueprints, on the other hand, can quickly develop into a challenging task.

These tools integrate seamlessly with other construction software, ensuring smooth workflows between different stages of a construction project. For example, data from takeoff software can be directly imported into project management or bidding software, eliminating the need for tedious data entry and minimizing errors.

The benefits of digital takeoffs extend further to reducing material costs. As the software offers greater precision, it reduces the chances of overestimation, thereby minimizing the risk of wasted resources. Additionally, the highly accurate estimates it provides aid in preventing shocks of unexpected costs cropping up during the construction process. Access to the NatCap website is another essential tool for accurate construction takeoff estimates because we can give transparent quotes and pricing promptly.

Knowledge and experience are the cornerstones of success in the construction industry, and at National Capital Industries, they form the basis of our approach to construction takeoffs. We’ve been around the block, specializing in everything related to construction, from safety equipment supply to other complex projects. As a trusted provider for the past 60 years, we’ve not just implemented but pioneered many industry practices.

NatCap aids in construction takeoff by providing upfront estimates of materials as well as many products for rent. Renting can cut a huge chunk of your project expenses down, especially if the necessary equipment is for a short-term or very specific project. From internal tools such as our sign calculator to our speedy customer service, you can ensure that your project is getting the best prices and quality equipment. Our equipment is ANSI and OSHA regulated so your employees can be fully protected with minimal liability.

To sum it all up, understanding and effectively implementing construction takeoffs can make a massive difference to the outcome of a project. By coupling traditional practices with the ability to rent construction supplies, you can introduce accuracy, speed, and efficiency to your projects.

Whether you’re in Baltimore, Washington D.C., Northern Virginia, or Delaware, National Capital Industries is here to help. We can guide you through the construction takeoff process, offer invaluable advice, and provide the right tools to make your project as efficient as possible. Because, at the end of the day, the success of your project is our success too, and we believe in building success stories together.

Contact us today to see how we can help make your construction process simple, accurate, and efficient!

Techteamdigitlab. “Two Methods of Quantity Take-off: Manual vs Digital.” RIB, 8 June 2023, ribccs.com/manual-vs-digital-quantity-take-off/.