Understanding the function of an attenuator amidst our complex road network systems and dealing with numerous transition options can be daunting. In this blog post, we aim to demystify this essential piece of safety hardware and introduce you to the world of attenuators.

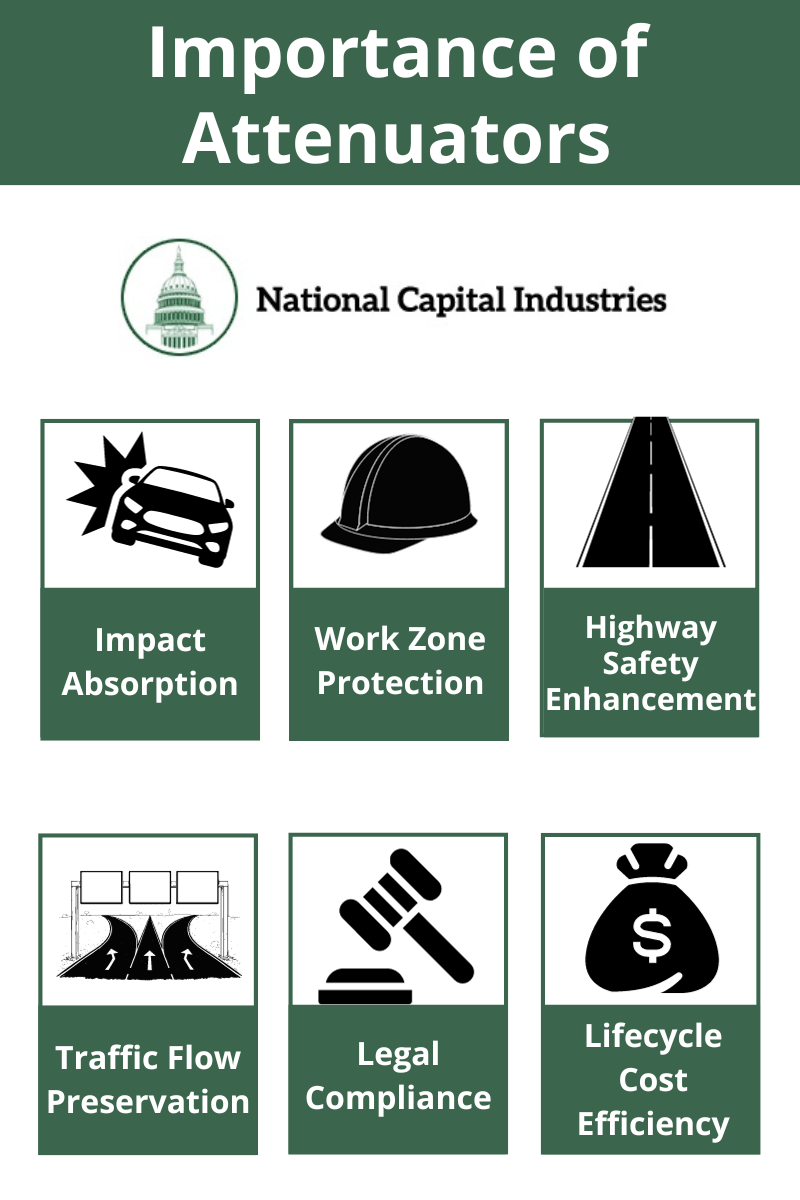

Attenuators, also known as crash cushions, play a critical role in highway safety. They are designed to absorb the kinetic energy of an errant vehicle, thus reducing the damage caused during a collision. There are several types of attenuators including crash attenuators, attenuator trucks, impact attenuators, and truck-mounted attenuators (TMA), each serving distinct functions but sharing a common purpose of providing full-width impact protection and safeguarding the lives of drivers, workers, and vehicles on the road.

In essence, attenuators are to roads what airbags are to cars – they protect against the worst outcomes in case of an accident. They can be found in multiple locations including the start and end of construction zones, interconnected roads, bridges, and piers. They play a significant role in reducing the severity of an accident from a full-speed crash to a more manageable event.

To envision an attenuator’s impact, imagine a high-speed vehicle losing control and heading toward a concrete barrier or roadwork area. It appears to be an impending disaster, but luckily, a crash attenuator is strategically placed there. Its purpose is to act as a buffer zone, effectively absorbing the energy from the impacting vehicle, thus mitigating the damage caused to the vehicle, and more importantly, potentially saving the life of the driver.

Crash attenuators, sometimes referred to as crash cushions or simply attenuators, are crucial components in road traffic safety. They have one essential purpose – protecting lives by absorbing and dissipating the energy of a collision, thereby reducing the impact force and risk of fatal injuries to the driver and surrounding people of an errant vehicle.

The design of crash attenuators is a result of decades of research and evolution, incorporating both the laws of physics and quantitative crash testing data. When a vehicle hits a crash attenuator, the attenuator responds by absorbing and reducing the crash energy. This process minimizes the force on the vehicle and its occupants, thereby effectively preventing potential fatalities and reducing the extent of injuries.

Crash attenuators come in various shapes and sizes to suit different traffic scenarios and provide safety for all, from drivers and passengers to errant vehicles and work zone occupants. Recognizable as barrels filled with sand, collapsible vinyl containers, or hydraulic systems mounted on trucks, these crash cushions are an integral part of highway safety efforts worldwide.

Despite their robust exterior, crash attenuators are designed for a smooth ride down, offering a protective cushion to an impacting vehicle and minimizing associated hazards for construction zones and highways. They are often used in conjunction with other traffic safety hardware or traffix devices, like concrete barriers or steel barriers, to provide a comprehensive safety solution on highways.

Impact attenuators, another significant subset of the attenuator family, hold a remarkable role in road safety. They come into play in situations where the impact and potential damage need to be minimized efficiently.

An impact attenuator is an essential traffic-management device designed to provide a protective barrier between errant vehicles and potentially hazardous objects, such as concrete structures, roadside equipment, or temporary work zones. In a nutshell, impact attenuators are expertly crafted devices meant to reduce the severity of potential crashes by absorbing the kinetic energy of an impacting vehicle.

Application-wise, impact attenuators find usage in various scenarios. They are often employed at the start or end of a construction zone, at exit ramps, or around bridge piers where vehicles might risk colliding with fixed objects. The protective mechanism of an impact attenuator comes into play in these precise situations. The refinement of design and factors like high density polyethylene structures and roll-ahead distance make these devices a lifesaver when a vehicle may have strayed off its course.

One popular and commonly seen variant of impact attenuators is the Sentry Longitudinal Energy Dissipater (SLED). Its non-redirective, gating functionality absorbs impact energy effectively, enhancing safety by allowing an errant vehicle to either come to a halt or continue its trajectory without escalating damage.

Impact attenuators as well as the installation and positioning of crash attenuators come under a range of test levels, as per the NCHRP Report 350, determining their capability to withstand different levels of impact. For instance, an attenuator with a high test level would be deployed in areas with high-speed traffic or where the probability of a frontal collision is high.

Products following specific installation manuals such as the one from the National Cooperative Highway Research Program, and MASH ensure that the crash attenuators are properly tested for optimal performance.

In testing traffic attenuators, MASH refers to the “Manual for Assessing Safety Hardware,” which provides guidelines for evaluating the performance of roadside safety features such as barriers, guardrails, and crash cushions. MASH criteria help to ensure these devices effectively slow down and redirect errant vehicles, reducing the severity of collisions.

During MASH testing, traffic attenuators are subjected to a series of controlled impact tests using vehicles of specified weights and traveling at defined speeds and angles. The performance of the attenuator is evaluated based on its ability to safely decelerate the vehicle, minimize the risk of injury to the occupants, and prevent vehicle penetration beyond the attenuator.

Through their vital role in reducing crash intensity and preventing serious damage, impact attenuators enhance road safety, saving lives and property every day. Consequently, they play a crucial role in every traffic safety and management plan, including federal highway administration guidelines, regardless of the location being a bridge deck, a construction work zone, or a high-speed highway.

Those yellow, red, or black devices you see on the roadside are more than just decoration – they are sophisticated safety systems designed to defy collisions, protect lives, and minimize the risk of roadside hazards. They serve as a silent guardian, preserving life on the road with their intelligent design and crucial functioning.

In the world of attenuators, there’s another type that employs a unique approach to traffic safety – the Truck Mounted Attenuator (TMA). As the name suggests, a TMA is an attenuator mounted on the back of a truck, providing a mobile solution for minimizing collision impacts in the work area.

TMA, much like its static counterparts, crash and impact attenuators, play a vital rule in absorbing and dissipating the kinetic energy of an errant vehicle during a crash. However, the difference lies in TMA’s use, as it is specifically designed to protect workers and equipment in mobile and stationary work zones.

A TMA combines the safety aspects of attenuators with the versatility and mobility of trucks, which are everyday vehicles seen on construction sites. The TMA provides a safe haven for roadside workers, preventing serious injuries by reducing the risk of secondary accidents and protecting against high-speed applications.

Easy to install and providing end treatment with Fitch barriers, Truck Mounted Attenuators are a critical safety device in roadside construction zones. These devices are especially functional and valuable during night-time work or on roads where traffic patterns frequently change. The use of a high-quality TMA can significantly lower worker exposure to risk and practically eliminate the possibility of life-threatening accidents on the job site.

National Capital Industries is your trusted partner for all your construction attenuator needs. At National Capital Industries, we come with a rich experience spanning over 60 years, driven by our mission to make work zone safety simple and accessible to all. With a reputation built on knowledge, we supply contractors with everything they need to get the job done including attenuators – and safety is always at the top of our list. Some value propositions gained from working with NatCap include:

Understanding and implementing appropriate safety measures is critical in any road construction or maintenance project. Attenuators play a vital role in this regard and choosing the right partner to supply these devices is a decision that could significantly impact the level of safety in your work zones. Reach out to us and experience the National Capital Industries difference today!

NCHRP Report 350 – Transportation Research Board, Transportation Research Board, 1993, onlinepubs.trb.org/onlinepubs/nchrp/nchrp_rpt_350-a.pdf.

Prasetya, Laksmana Widi, et al. “Design of Crashworthy Attenuator Structures as a Part of Vehicle Safety against Impact: Application of Waste Aluminum Can-Based Material.” Theoretical and Applied Mechanics Letters, Elsevier, 6 Mar. 2021, www.sciencedirect.com/science/article/pii/S2095034921000428.

“Kinetic Energy.” Encyclopædia Britannica, Encyclopædia Britannica, inc., 17 Oct. 2023, www.britannica.com/science/kinetic-energy.

Bowers, Becca. “Are You Ready for MASH Barrier Testing Requirements?” OTW Safety, 20 Feb. 2020, otwsafety.com/blog/mash-barrier-testing/.